05th Jan 2024

Plane locks and hasps are essential tools for the security of equipment. Additionally, they play an integral role in OSHA’s lockout / tagout regulations.

Electricians frequently encounter challenges when working at various job sites. To overcome this obstacle, many electricians prefer having multiple hasp/lock combinations on hand so they can work more quickly and securely.

Plane locks are devices installed on aircraft to prevent movable control surfaces from moving while the aircraft is parked. This is particularly crucial for reversible controls, which tend to move due to wing movement when parked.

According to the invention, a door-lock system 10 works by selectively activating an inner door 12 and outer door 14 that define an area 11 between them. This restricted area is known as the cockpit area, located within the forward fuselage of an airplane and designed as either a pilot’s cabin or utility space extending between it and the first class section of an aircraft.

Advantageously, the innovative door-lock system works to prevent unauthorized entry into the cockpit area – a critical area for aircraft safety. Furthermore, it acts as a deterrent to potential hijackers by keeping them away from entering the cockpit area.

In addition to a door-lock system, there are several portable security devices that can be placed on an aircraft’s flight controls. One such item is a prop lock, which uses either tempered and toughened steel chain or flexible steel cable inside an abrasion-resistant sleeve to stop the pilot’s throttle from moving. This inexpensive yet visible device serves as a deterrent for would-be thieves.

A hasp is a type of lock that can be used to secure doors and other equipment. They are typically made of metal in various lengths and styles, so you can find one suitable for your requirements.

Hasps are an ideal way to guarantee the integrity of group lockout tagout procedures. Employees can install padlocks and Danger Do Not Operate tags in order to isolate machinery during re-energizing processes. Furthermore, individual re-energizing procedures that take place within a specific area may benefit from having hasps installed.

Hasps can be utilized to quickly secure roll-up doors. They come in various sizes with various locking points, so you can find one that best meets your requirements.

Hasps are an excellent way to safeguard your possessions. You can use them in sheds and cabinets, as well as lock gates and fences, which help prevent them from being opened accidentally.

Hasps can also be used for securing other objects, such as tools or tool chests. Available in a range of materials – aluminum and non-conductive steel – so you can find one that suits your requirements perfectly.

Plane locks are a reliable security measure that prevents equipment from starting up, releasing energy, or moving. They can be utilized to secure one or multiple doors and have been designed to meet OSHA’s Lockout/Tagout standard.

Hasps are an essential element of locking systems and are typically combined with a padlock to secure equipment to its frame. They come in various sizes and configurations to fit different door types, such as swinging, sliding, or double ones.

A hasp is composed of a hingeable arm and a protective shroud at its distal end. The latter features an angle-related pad lock hoop engagement hole located along a diagonal within the shroud enclosure to facilitate easier padlock shackle insertion after installation.

The hasp and keeper assembly should include a pair of eyes that can be secured together using an appropriate lock, such as a padlock. These eyes should be situated at the meeting faces between the door and jamb, creating a separation slot offset from their edges for added protection against cutting or tampering with the locks.

When it comes to securing luggage or other items, both airplane locks and hasps can be beneficial. However, there are some key distinctions between them. One major distinction is that the hasp encloses and closely embraces the eyes of the lock, while a plane lock is designed to thwart forceful attacks on its pad as well as overlying shroud plates that surround its rear edge.

For aircraft doors, a specially formed hasp and keeper assembly is combined with a round lock to provide high levels of security. This combination has the benefit of being relatively straightforward to assemble, as it mounts against the rear face rather than the front face of the structure.

The hasp and keeper assembly consists of a pad plate 22 and keeper pad 24; both mounted against the rear face of the door structure in an identical fashion. The pad plate 22 is constructed from steel with a rectangular shape featuring a semicircular cutout 38 at its right edge; similarly, keeper pad 24 is also made from steel but features a similar cutout 42 at its right edge.

This hasp and keeper assembly is designed to receive the slidable bolt 26 of lock 10, providing protection from prying or other forced entry methods. Once engaged with apertures created by forward-projecting eyes 18 and 20, these locking mechanisms become solidly locked together.

Another feature of this hasp and keeper assembly is its offset separation plane between the pad of the hasp and keeper pads, offset in a direction toward the door jamb to place their eyes opposite each other at an opposite point on the center of the door separation slot 48. This further improves security against cutting as well as compatibility with latch lock mechanisms 20.

Another key benefit of this hasp and keeper assembly for use with the plane lock is its rounded front surface which helps prevent forceful attacks on the pad. Overlying shroud plates also surround the rear edge of the lock, providing another rounded front surface to further protect against piercing or other forced entry attempts on the pad.

The lock is designed to enclose the eyes of both the hasp and keeper so that a key can only be inserted through a guard disc 82 located in a recess in the housing. Once in place, this key rotates the guard disc 82 and retracts bolt 26, engaging its apertures on eyes 18 and 20, respectively.

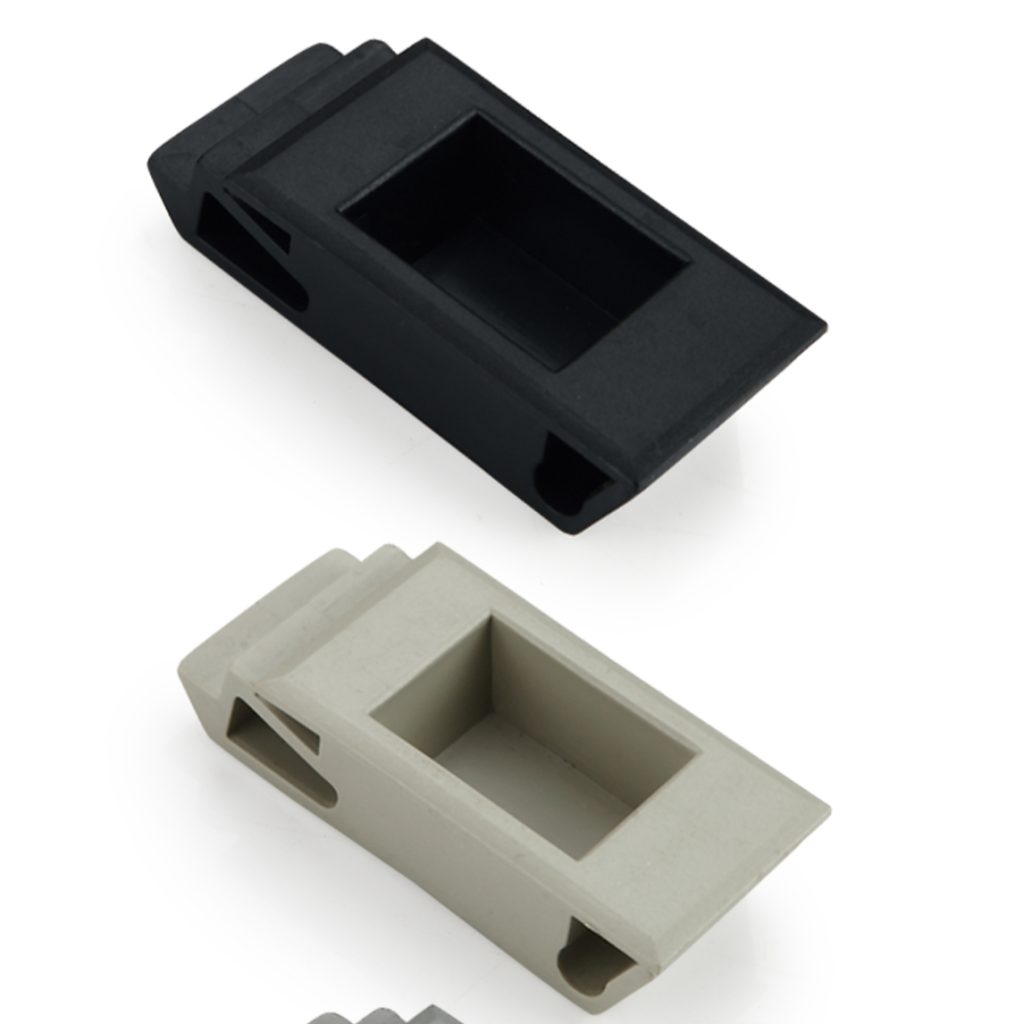

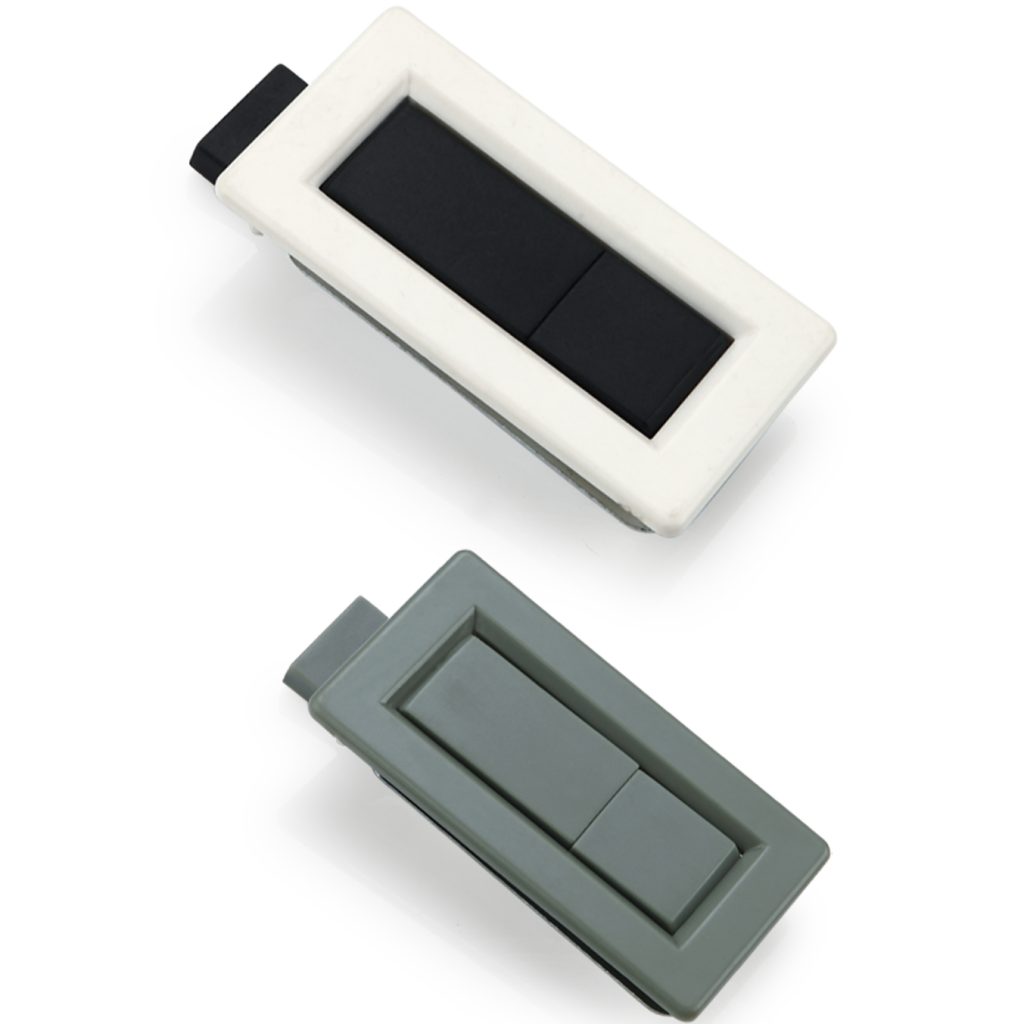

ZONZEN is an experienced OEM Industrial Locks Manufacturer that offers professional accessory solutions to customers in the communications, power, and mechanical equipment industries. Our products have been featured by leading brands like Schneider, Emerson, Weitu, ABB, Siemens, Huawei, ZTE CRRC Xuji, and Delta.

Our Customer service is unsurpassed. We have well trained customer service representatives that are ready to help you with your next project be it large or small.

Our R&D team keeps developing new items for customers all over the world to ensure that we keep the flow of new hot selling point. If you have any questions or suggestions, please do not hesitate to contact us for further assistance.