13th Apr 2023

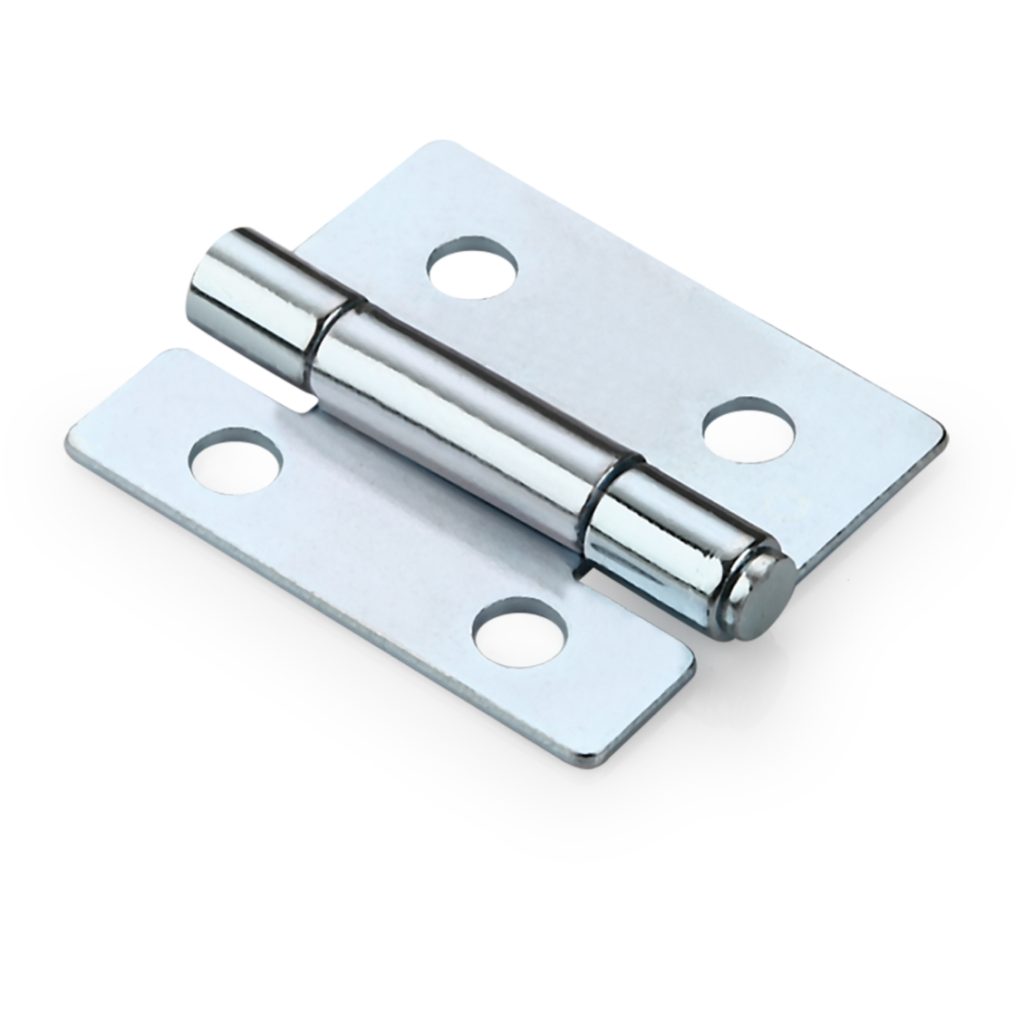

Hinges are essential parts of machine-made equipment. They come in various shapes and sizes to help connect doors, boxes, and other objects by pivoting motion.

Hinges can be produced through casting, extrusion, forming, or milling, depending on the hinge profile, material, cost, and available technology. Secondary processes like heat treatment, galvanizing, coating, painting, or polishing may then be employed to complete the piece for optimal aesthetic appeal.

Hinges are vital components for the safety and efficiency of machine-made equipment. They keep doors, panels, and other components secured, so they do not separate or crack under bending forces.

Hinges’ durability is determined by several factors, including their base material, frequency of use, and exposure to harsh environmental elements.

Hinges must also be resistant to corrosion and rust, as these factors can lead to fatigue and premature failure if left unprotected.

Hinges must meet certain specifications, which is why they’re typically made from various metals such as steel, stainless steel, brass, and aluminum. Some even receive coatings to increase their resistance against corrosives.

Hinges are fundamental mechanical devices that enable two parts to pivot relative to one another around a fixed axis. They can move in an arc or with 360 degrees of freedom, depending on the type of hinge used.

Fasteners provide a cost-effective and straightforward method for connecting rigid elements in an assembly. They have many uses, such as doors and other equipment.

On the market, there is a vast selection of hinges to suit any application. Whether you need heavy-duty hardware for industrial machinery or delicate butterfly hinges for decorative purposes, we can assist you in finding the ideal product to meet your requirements.

Hinges can be constructed from a variety of materials, such as steel, stainless steel, aluminum, brass, and bronze. Ultimately the choice you make will determine the cost and durability of your final product.

Hinges are fastener hardware that connects two pieces of equipment together and allows angular movement around a fixed axis of rotation. Hinge designs can typically be tailored to meet the specifications of the manufacturer.

Hinges can be constructed from a range of metals, such as steel, stainless steel, nickel, brass, chrome, and copper. Each offers its own advantages in terms of durability, tensile strength, corrosion resistance, ductility, and aesthetic appeal.

Industrial hinges can be manufactured from metals as well as the plastic material for cost-effective durability. These hinges tend to be heated, rust, and chemical resistant without needing lubrication, making them an ideal choice for industrial applications.

When selecting a hinge, it’s essential to take into account your product’s intended use and expected life cycle. For instance, if you open your refrigerator five times daily, then perhaps you do not need an item that can withstand 100,000 cycles.

Hinges are typically produced using a range of processes, such as casting, extruding, forming, and milling. The manufacturer typically selects which process to use depending on the hinge profile, material costs, and available technology.

Hinges are typically constructed out of metals such as stainless steel, chrome, copper, nickel, and solid brass for strength, corrosion resistance, and ductility.

Cold-rolled steel is another viable option, often chosen for manufacturing applications due to its superior strength and longevity.

Hinge manufacturers also provide a range of accessories, such as tip-on touch latches, angle restriction clips, doorstops, and compact adaptors, to enhance the appeal and functionality of their hinges. These may protect them from damage or rust while cutting down installation time and cost.

Hinges for machine-made equipment are commonplace across a range of industries. You’ll find them on items like cabinets, doors, windows, gates, lockers, and tables alike – perfect places to hang your laundry!

Hinges must meet certain specifications to be effective, including the dimensions and weight of objects to which they attach, their anticipated use frequency, and any environmental conditions they will be exposed to.

Hinges that will be exposed to outdoor environments need materials resistant to corrosion. Aluminum and stainless steel provide excellent resistance in this regard.

ZONZEN offers a selection of safety hinges with integrated safety switches for monitoring guard doors and covers on machine and production equipment. These devices interrupt a protective circuit and turn off the power supply when opened, shielding operators from harm’s way.

Hinges are an integral component of machine-made equipment. Their pivoting motion allows doors and covers to securely hold equipment and housings in place while offering various materials, fastening options, and designs for consideration.

When selecting a hinge, it’s essential to take into account the weight it will support. This will dictate the hinge’s dimensions and material.

When manufacturing hinges, there are a few methods to choose from – casting, extruding, forming, and milling. Each has its own advantages and drawbacks but is generally chosen depending on the hinge profile, material costs, and available technology.

Hinges typically feature two flat surfaces called leaves that are joined together by knuckles or barrels, which allow the hinge to bend. These knuckles also act as anchor points for screws and bolts, attaching the hinge to whatever it’s holding onto. Pins can then be inserted between these knuckles to securely join the leaves together, as well as help rotate the hinge itself.

Hinge design and manufacturing is a delicate process that must take into account various elements. The hinges themselves must be flexible enough for easy manipulation but strong and long-lasting enough to withstand regular usage.

When selecting a hinge, the material used can make an important difference in its performance in the environment where it will be installed. Some materials provide better weather resistance than others.

Brass hinges, for instance, can be a suitable option in applications where they will come into direct contact with external environments. However, this material may not be as durable or resistant to wear and tear as cold-rolled steel or stainless steel due to its lower carbon content.

When manufacturing hinges, the best method is injection molding. This involves forcing heated plastic through a die and shaping it into the desired shape.

ZONZEN is a leader in electronic locks and hardware locks for numerous applications and markets. Their strict manufacturing process and ISO9001 quality management system enable them to offer industrial and commercial lock solutions to customers around the world.

Our Customer service is unsurpassed. We have well trained customer service representatives that are ready to help you with your next project be it large or small.

Our R&D team keeps developing new items for customers all over the world to ensure that we keep the flow of new hot selling point. If you have any questions or suggestions, please do not hesitate to contact us for further assistance.